Cost-Effective Electrostatic Coating Services

Electrostatic paintings utilize a specialized process that applies paint through an electrostatic charge, resulting in a smooth, even coating with minimal overspray. This technique is widely used in industrial and commercial settings to achieve durable finishes on various surfaces. The process involves charging paint particles, which are then attracted to grounded surfaces, ensuring precise application and efficient use of materials.

Advanced equipment used in electrostatic painting ensures even application and high-quality finishes. Modern systems include spray guns, booths, and controllers designed for efficiency and precision.

The process involves charging paint particles and applying them to surfaces with an electrostatic field, resulting in uniform coverage and minimal waste.

The final result showcases a smooth, durable, and high-quality finish that adheres well to various surfaces, including metal, plastic, and wood.

Electrostatic painting is recognized for its efficiency and high-quality results. The technique reduces paint wastage and provides a consistent coating that enhances the appearance and longevity of surfaces. It is particularly beneficial in environments requiring corrosion resistance and a flawless finish, such as manufacturing plants, automotive industries, and architectural applications.

The duration depends on the size and complexity of the project, but typically, a professional can complete surface preparation and painting within a few hours to a few days.

Preparation involves cleaning and priming surfaces, followed by masking off areas as needed. The application uses specialized electrostatic spray equipment, and curing times vary based on the type of paint used.

Professional electrostatic painters ensure proper surface preparation, optimal equipment use, and high-quality finishes. Their expertise reduces errors, enhances durability, and guarantees a uniform appearance.

The electrostatic painting process is a precise and efficient method that requires specialized skills and equipment. Engaging experienced professionals ensures that the project is completed correctly, with optimal results that meet industry standards for quality and durability.

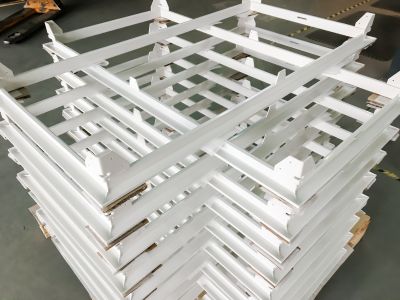

Showcases a smooth, uniform finish on metal surfaces, demonstrating the effectiveness of electrostatic application.

Depicts a professional applying paint using electrostatic spray equipment on a large surface.

Features durable electrostatic coatings on industrial equipment, highlighting the quality of the process.

For those seeking high-quality, durable finishes with efficient material use, electrostatic painting offers a reliable solution. The technique ensures a consistent appearance and long-lasting results, making it suitable for a variety of applications across different industries.

Interested in a detailed quote for electrostatic painting services? Filling out the contact form provides an opportunity to discuss project specifics and receive tailored information to meet individual needs.