Optimal Conditions for Electrostatic Painting

Electrostatic painting is most effective when environmental conditions are optimal. Temperature, humidity, and surface cleanliness play vital roles in achieving high-quality finishes. The ideal temperature range for electrostatic painting typically falls between 60°F and 85°F, with low humidity levels to prevent paint defects.

Perform electrostatic painting during dry, mild weather to ensure proper paint adhesion and curing. Avoid rainy or extremely humid days.

Schedule painting after thorough cleaning and surface preparation to maximize paint adherence and finish quality.

Plan painting projects during periods of low activity to allow sufficient curing time without disturbance.

Spring and fall often provide suitable weather conditions, avoiding extreme cold or heat.

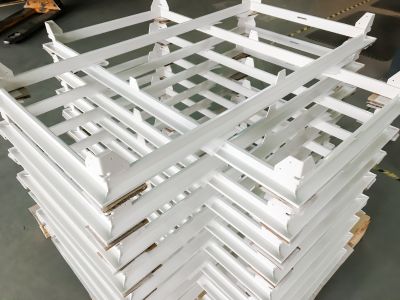

A technician applies electrostatic paint to a large metal surface, demonstrating even coverage.

Surface cleaning and priming before electrostatic painting ensures optimal results.

Finished electrostatic painted surface curing in a controlled environment.

Ways to make Electrostatic Paintings work in tight or awkward layouts.

Popular materials for Electrostatic Paintings and why they hold up over time.

Simple add-ons that improve Electrostatic Paintings without blowing the budget.

| Environmental Factors | Recommended Conditions |

|---|---|

| Temperature | Between 60°F and 85°F |

| Humidity | Below 50% |

| Surface Cleanliness | Free of dust, grease, and rust |

| Weather Conditions | Dry and mild |

| Indoor Conditions | Stable climate with controlled temperature and humidity |

Electrostatic paintings are widely used in industrial, automotive, and architectural applications due to their efficiency and high-quality finish. This process involves applying charged paint particles to a grounded surface, resulting in uniform coverage with minimal overspray. Studies show that electrostatic painting can increase transfer efficiency to over 90%, reducing material waste and improving finish quality.

The process is particularly suitable for large or complex surfaces, where traditional methods may struggle to ensure even coverage. Proper timing and environmental control are crucial for achieving optimal results. The technique also offers advantages in applying coatings to difficult-to-reach areas, making it a preferred choice in many industrial settings.

High-voltage electrostatic spray guns in use during a coating process.

Cleaning and priming surfaces before electrostatic application.

A smooth, evenly coated metal surface post electrostatic painting.

Electrostatic painting on large industrial equipment.

High-end options that actually feel worth it for Electrostatic Paintings.

Finishes and colors that play nicely with Electrostatic Paintings.

Little measurements that prevent headaches on Electrostatic Paintings day.

A 60-second routine that keeps Electrostatic Paintings looking new.

Interested in electrostatic painting for your project? Filling out the contact form can provide more information and help determine the best timing and conditions for optimal results.